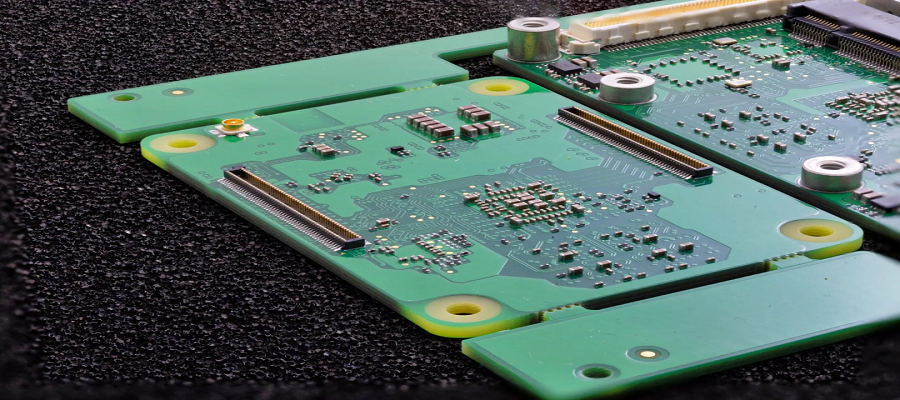

Within a week of being approved by the Union Cabinet, the Ministry of Electronics and Information Technology on Tuesday notified the new scheme for domestic manufacturing of semiconductor wafer fabrication facilities. There is significant interest, Minister of Electronics and Information Technology Ashwini Vaishnaw said in an interview, from both global and domestic companies. Edited excerpts:

Within a week of being approved by the Union Cabinet, the Ministry of Electronics and Information Technology on Tuesday notified the new scheme for domestic manufacturing of semiconductor wafer fabrication facilities. There is significant interest, Minister of Electronics and Information Technology Ashwini Vaishnaw said in an interview, from both global and domestic companies. Edited excerpts:

There have been schemes to encourage domestic manufacturing of semiconductor chips and fabrication, which are very similar to what has been announced this time. Those schemes did not take off. What is different this time?

Three things are very different. The first is that today there is an ecosystem that can consume the chips which are manufactured. Electronic manufacturing is today a $75-billion industry, on the way to becoming $250 billion in 5 years. That is a very big difference. Secondly, all along, we had been thinking only of silicon fabrication. This time, the thought process is for the entire ecosystem, which includes silicon fabrication, display fabrication, 15-odd compound semiconductor fabrication and the entire design unit.

We were thinking of 50 companies, but looking at the response we are getting, we might go beyond 100 companies. Then there are the 85,000 semiconductor engineers. So, that is the second difference. The third is a commitment for 20 years. So, instead of a one-off project, here we are committing to the industry that we have a roadmap of 20 years, in which talent, more fabrication units, and co-operation with the states will be considered. It is not based on our thinking but the way the industry has given us feedback. There is very extensive consultation with the industry, designers, equipment manufacturers, state governments, consumers and academia.

How many applicants are you expecting overall?

In the silicon and display fabrication units, these are very big-ticket items. That will always be a very limited area because there are only four or five companies who dominate this entire industry. But in the compound semiconductor and the ATMP (assembly, testing, marking and packaging ) segment, which is what goes into automobile, power electronics, and telecom equipment, we might even exceed 15 applicants, which is what we had targeted earlier. In design, of course, we had targeted 50 applications, but might get more than a hundred.

Semiconductors is a very niche industry. There are requirements such as extremely pure water. Are there any specific geographies you have in mind for the industries?

Ultra-pure water is always manufactured. So, wherever plant is put, it will be part of the unit. So, that is not geography dependent. Double or triple redundant power is a design issue, which can be very easily handled. The third thing which people look for is high-tech engineers. So, what is the kind of facility that the applicant would be providing for them, and what kind of ambiance these engineers like to live in. That will also have a play in the decision for the unit.

There are some domestic companies such as Tata, which have expressed interest in semiconductor chip manufacturing. Is the Ministry consulting them?

All domestic companies interested in manufacturing these products have been consulted.

What will the scheme entail to support demand aggregation?

Luckily, electronics manufacturing is today a very well established industry. So, that is going to primarily have the consumption of these chips. The automobile industry, which is the second big consumer, is a highly organised industry. The power electronics industry, which is a bit fragmented at the lower voltage side, is again very organised at the larger level. And then there is the telecom equipment manufacturing.

These are the four large consumers. That is the level of aggregation. We will not be saying that we will buy and tell you the market. Our value add is more in guiding them. The industry itself is very organised.

Have any global companies shown interest?

It would be unfair to give any names. One prominent companies said all the countries around the world are putting in multiples of tens of billions of dollars, which is par for the course. What we have done different, according to them, is the 85,000 semiconductor engineer commitment. For the second plant, and the subsequent growth, you need the local talent. Otherwise, how do you grow this industry?

For the design linked incentive scheme, will local companies get manpower training from foreign experts?

We have about 60,000 design engineers already working in India, with the biggest names in the industry, which are almost all the global companies. Many of them will have their own startups in future. When the brain is India, why should the IP (intellectual property) also not be Indian?

Interview Courtesy:- Ashish Aryan